We sat down and asked some of our service technicians for a few quick tips on things you can do to keep your belts running in top condition.

Inspect the Belt for Cracks

When inspecting the belt you may want to remove it from your machine to get it into good lighting conditions to be able to check it for cracks. When the belt is under tension it may close the cracks and they will be hard to detect while on the machine. You may also notice small cracks developing from dry conditions that can be caused by too much exposure to sun light.

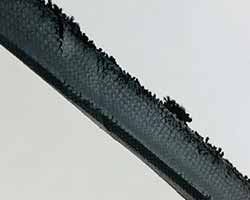

Inspect the Belt for Fraying

Fraying can be caused by many conditions. Examples include an old belt that is nearing the end of its wear life, there is debris that is rubbing on the belt while in operation, or you have a idler pulley that is not operating correctly and is adding excessive heat to the belt from added friction.

How Do I Extend the Life of My Belts?

The best approach to damage prevention is to keep the top surface of your deck clear of debris such as sticks, leaves and excessive grass clippings. Another key element is proper operation of all idler pulleys. Making sure the idler pulleys operate freely and have no damage to the pulley surface that the belt is in contact with will prevent damage to the belt.

From all of us here at Green Farm Parts, we hope you learned a little something about your John Deere belts. Speaking of belts, you can find drive belts, V-belts and any other belt for your machine every day at our John Deere Belts Online Catalog.